Wetted parts:

●Mild steel Q235B with epoxy coating

●Mild steel Q235B with FRP lining

●Stainless steel SUS304

●Stainless steel SUS316L

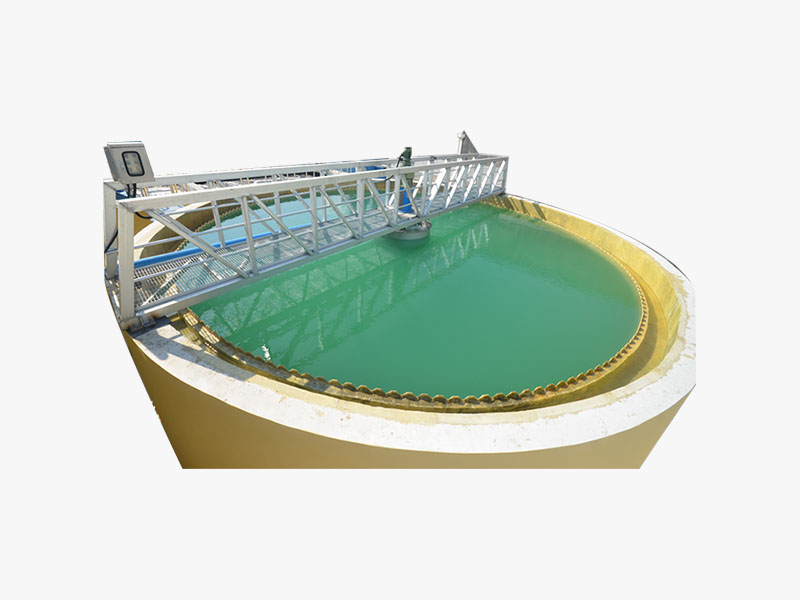

Working bridge:

●Mild steel main structure+FRP platform

●Stainless steel main structure+FRP platform

●Hot galvanized steel main structure+FRP platform

●Or concrete structure by clients

220V/240V/380V/400V/415V/440V/460V/575V

How can I send you the RFQ ?

A:You can contact us by email or call or leavel message on the website.

What info do I need provide you to make the proposal?

A:Pls provide us flowrate per hour,wastewater industry, wastewater quality(SS,BOD,COD,FOG etc) to be treated by our equipments, as detalied as possible. If you have jar test photo or video,that would be also good.

Are you the direct manufacturer with workshop?

A:Yes.We fabricate thoese equipments in our own workshop from material cutting,bending,welding,painting,assembling to test and commissioning before delivery.Occupied area is around 10,000 square meters.

What material can you offer? And what’s the most popular option?

A:We can fabricate carbon steel with epoxy coating or FRP lining, SUS304, SUS316L .Generally for ordinary wastewater not corrosive, carbon steel with epoxy coating is the most popular and cost-effective one.If corrosive, carbon steel with FRP lining is also a good option.

How to ship your equipments?

20’GP ,40’HQ or 40’FR (large flowrate )

How to install your equipment after receiving the goods?

A: Detalied manual book will be provied.We can also provide remote video guidance if necessary.Besides,our equipment is designed as a complete system, and automatic operation.So generally you only need connect the inlet/outlet nozzle, and extrernal cable .We have lots of experience in oversea projects,we are confident in helping you eliminate this concerns.

Do you provide after sales services as my project is not in China?

A:Of coure.Our sales and technician will reply to you on the day or next day (time gap) .We think highly of after sales service as a reputed DAF and Lamella clarifier brand manufacturer.