Products

Contact Us

- Room 501-5, Building 8, Longdong Avenue 3000, Pudong New District, Shanghai, China

- +86-18918301201

- Grace Xia

- jorsun01@jorsun.com.cn

Introduction

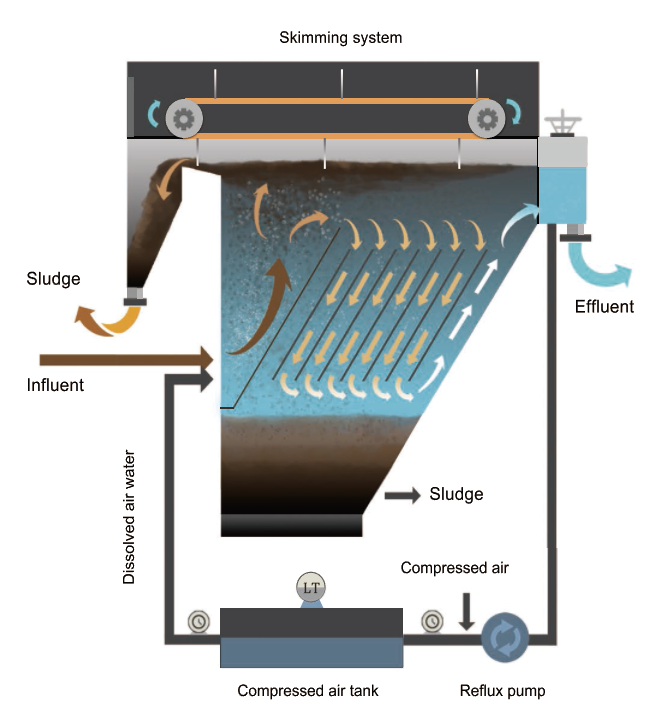

Integrated DAF System IDAF/IDAF2 has been known and applied widly as one of the most effective and economic ways to remove suspended solids (SS),fats, oils and grease (FOG), phosphorus (P) from industrial wastewaters by the generation of micro bubbles.

Jorsun DAF is an innovation combined with traditional dissolved air flotation design theory and modern technology after years of research and application.DAF is based on a physical / chemical process.Wastewater is dosed with treatment chemicals upstream of the DAF inlet to form flocs.

When those flocs enter to the DAF chamber,massive of microbubbles attach to the flocs, and bring them floating to the top.The floating solids are harvested by DAF’s top skimmer. After the separation process, clean effluent will be collected and discharged.

The generation of micro bubbles is through the air saturation vessel and air diffuser plates.A portion of the DAF effluent is recycled to the air saturation vessel to mix with air by venturi jet under high pressure,and form air dissovled water(white water) .When the air dissoveld water flow to the air diffuser plates, the sharp reduction of pressure will make the microbubbles release from the air dissolved water,and form massive microbbubles.

JORSUN Dissolved Air Flotation Plants are successfully operated for a wide variety of industrial and municipal applications, such as:

B- Beverage; Biological effluent;

D- Dairy (milk,ice cream,yogurt etc);

E- Electrinic;

F- Farm; Food(noodle,cookie,bread ,starch,sauce,flavours and fragrances etc);

L- Leachate

M- Meat processing(chicken,beef etc) ; Mine; Municiple;

O- Oil refinery;

P- Package (fruit,shrimp,food etc); Painting; Paper; Pharmacy;

R- River; Rubber glove;

S- Semiconductor; Slaughter; Steel;

T- Textile and dyeing;

U- Underground water;

W- Washing wastewater(plastic,workshop,car,container etc) ;

● Maximum TSS,FOG removal efficiency with JORSUN high efficient air dissolved system (99.9% air releasing effiency).

● Experience from over 2,000 applications in a variety of fields.

● Minimize footprint with JORSUN compact design.

● Save installation time .JORSUN DAF units are deliveryed as prefabricated units . Very easy for installation.

● Quick in response to provide excellent international services.Served clients are over 50 countries aross the world.

● Various constructed material. Carbon steel epoxy coating or FRP lining, stainless steel SUS304 or SUS316L,duplex steel 2205 or 2507.

|

Model |

Capacity |

Power(kw) |

Dimension(m) |

Pipe connention(DN) |

||||||||

|

(m3/h) |

Recycle |

Air |

Skimming |

Coagulation |

Flocclation mixer |

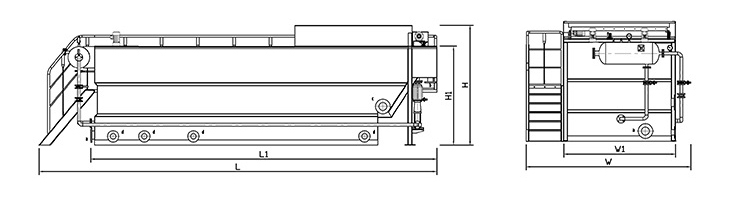

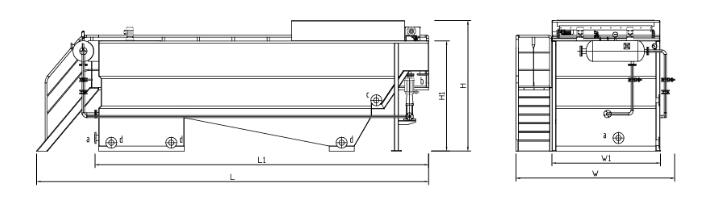

L/L1 |

W/W1 |

H/H1 |

(a) |

(b) |

(c) |

|

|

IDAF-002 |

~2 |

0.75 |

0.55 |

0.2 |

0.37 |

0.25 |

3.8/2.9 |

2.4/1.16 |

2.1/1.7 |

50 |

50 |

80 |

|

IDAF-003 |

~3 |

0.75 |

0.55 |

0.2 |

0.37 |

0.25 |

4.1/3.2 |

2.4/1.16 |

2.1/1.7 |

50 |

50 |

100 |

|

IDAF-005 |

~5 |

1.1 |

0.55 |

0.2 |

0.37 |

0.25 |

4.4/3.5 |

2.4/1.16 |

2.1/1.7 |

80 |

80 |

100 |

|

IDAF-010 |

~10 |

1.5 |

0.55 |

0.2 |

0.37 |

0.25 |

5.0/3.9 |

2.92/1.66 |

2.3/1.9 |

100 |

100 |

100 |

|

IDAF-015 |

~15 |

2.2 |

0.75 |

0.2 |

0.37 |

0.25 |

6.1/5.0 |

2.92/1.66 |

2.3/1.9 |

100 |

100 |

100 |

|

IDAF-020 |

~20 |

3.0/5.5 |

0.75 |

0.2 |

0.37 |

0.25 |

6.2/5.1 |

3.1/2.16 |

2.3/1.9 |

150 |

100 |

100 |

|

IDAF-030 |

~30 |

3.0/5.5 |

0.75 |

0.2 |

0.37 |

0.25 |

7.7/6.6 |

3.1/2.16 |

2.3/2.0 |

150 |

150 |

150 |

|

IDAF-040 |

~40 |

3.0/5.5 |

0.75 |

0.2 |

0.75 |

0.37 |

7.9/6.7 |

3.6/2.7 |

2.7/2.3 |

200 |

150 |

150 |

|

IDAF-050 |

~50 |

7.5 |

1.5 |

0.2 |

0.75 |

0.37 |

9.0/7.8 |

3.6/2.7 |

2.7/2.3 |

200 |

150 |

150 |

|

IDAF-060 |

~60 |

7.5 |

1.5 |

0.2 |

0.75 |

0.37 |

9.3/8.1 |

4.0/3.0 |

2.7/2.3 |

250 |

200 |

150 |

|

IDAF-070 |

~70 |

11 |

1.5 |

0.2 |

0.75 |

0.37 |

11.1/9.9 |

4.0/3.0 |

2.7/2.3 |

250 |

200 |

150 |

|

IDAF-080 |

~80 |

11 |

1.5 |

0.2 |

1.5 |

0.37 |

11.7/10.4 |

4.0/3.0 |

2.7/2.3 |

250 |

200 |

150 |

|

IDAF-100 |

~100 |

15 |

2.2 |

0.2 |

1.5 |

0.37 |

12.9/11.8 |

4.4/3.4 |

2.7/2.3 |

300 |

250 |

150 |

|

IDAF-120 |

~120 |

15 |

2.2 |

0.2 |

1.5 |

0.37 |

13.9/12.8 |

4.4/3.4 |

2.7/2.3 |

300 |

250 |

150 |

|

IDAF-150 |

~150 |

18.5 |

2.2 |

0.2 |

1.5 |

0.37 |

14.1/13.0 |

4.4/3.8 |

2.7/2.3 |

350 |

300 |

150 |

|

Model |

Capacity |

Power(kw) |

Dimension(m) |

Pipe connention(DN) |

||||||||

|

(m3/h) |

Recycle |

Air |

Skimming |

Coagulation |

Flocclation mixer |

L/L1 |

W/W1 |

H/H1 |

(a) |

(b) |

(c) |

|

|

IDAF2-010 |

~10 |

1.5 |

0.55 |

0.2 |

0.37 |

0.25 |

5.0/3.9 |

2.92/1.66 |

2.6/2.2 |

100 |

100 |

100 |

|

IDAF2-015 |

~15 |

2.2 |

0.75 |

0.2 |

0.37 |

0.25 |

6.1/5.0 |

2.92/1.66 |

2.6/2.2 |

100 |

100 |

100 |

|

IDAF2-020 |

~20 |

3.0/5.5 |

0.75 |

0.2 |

0.37 |

0.25 |

6.2/5.1 |

3.1/2.16 |

2.6/2.2 |

150 |

100 |

100 |

|

IDAF2-030 |

~30 |

3.0/5.5 |

0.75 |

0.2 |

0.37 |

0.25 |

7.7/6.6 |

3.1/2.16 |

2.6/2.2 |

150 |

150 |

150 |

|

IDAF2-040 |

~40 |

3.0/5.5 |

0.75 |

0.2 |

0.75 |

0.37 |

7.9/6.7 |

3.6/2.7 |

2.6/2.2 |

200 |

150 |

150 |

|

IDAF2-050 |

~50 |

7.5 |

1.5 |

0.2 |

0.75 |

0.37 |

9.0/7.8 |

3.6/2.7 |

2.6/2.2 |

200 |

150 |

150 |

|

IDAF2-060 |

~60 |

7.5 |

1.5 |

0.2 |

0.75 |

0.37 |

9.3/8.1 |

4.0/3.0 |

3.0/2.2 |

250 |

200 |

150 |

|

IDAF2-070 |

~70 |

11 |

1.5 |

0.2 |

0.75 |

0.37 |

11.1/9.9 |

4.0/3.0 |

3.0/2.2 |

250 |

200 |

150 |

|

IDAF2-080 |

~80 |

11 |

1.5 |

0.2 |

1.5 |

0.37 |

11.7/10.4 |

4.0/3.0 |

3.0/2.6 |

250 |

200 |

150 |

|

IDAF2-100 |

~100 |

15 |

2.2 |

0.2 |

1.5 |

0.37 |

12.9/11.8 |

4.4/3.4 |

3.0/2.6 |

300 |

250 |

150 |

|

IDAF2-120 |

~120 |

15 |

2.2 |

0.2 |

1.5 |

0.37 |

13.9/12.8 |

4.4/3.4 |

3.0/2.6 |

300 |

250 |

150 |

|

IDAF2-150 |

~150 |

18.5 |

2.2 |

0.2 |

1.5 |

0.37 |

14.1/13.0 |

4.4/3.8 |

3.0/2.6 |

350 |

300 |

150 |

Remark: To make the most suitable proposal, we will need know flowrate, wastewater source,wastewater quality (SS,BOD,COD,FOG etc ).

● Micro bubble generation technology

● Solid-liquid separation technology in scum zone

● Box type skimming system with patent

● Apply sedimentation theory for DAF2 series

● Laminar flow technology in separation zone for SDAF series

● Mild steel Q235B with epoxy coating

● Mild steel Q235B with FRP lining

● Stainless steel SUS304

● Stainless steel SUS316L

220V/240V/380V/400V/415V/440V/460V/575V

GB/JIS10K/ANSI150/DIN/BS

How can I send you the RFQ ?

A:You can contact us by email or call or leavel message on the website.

What info do I need provide you to make the proposal?

A:Pls provide us flowrate per hour,wastewater industry, wastewater quality(SS,BOD,COD,FOG etc) to be treated by our equipments, as detalied as possible. If you have jar test photo or video,that would be also good.

Are you the direct manufacturer with workshop?

A:Yes.We fabricate thoese equipments in our own workshop from material cutting,bending,welding,painting,assembling to test and commissioning before delivery.Occupied area is around 10,000 square meters.

What material can you offer? And what’s the most popular option?

A:We can fabricate carbon steel with epoxy coating or FRP lining, SUS304, SUS316L .Generally for ordinary wastewater not corrosive, carbon steel with epoxy coating is the most popular and cost-effective one.If corrosive, carbon steel with FRP lining is also a good option.

How to ship your equipments?

20’GP ,40’HQ or 40’FR (large flowrate )

How to install your equipment after receiving the goods?

A: Detalied manual book will be provied.We can also provide remote video guidance if necessary.Besides,our equipment is designed as a complete system, and automatic operation.So generally you only need connect the inlet/outlet nozzle, and extrernal cable .We have lots of experience in oversea projects,we are confident in helping you eliminate this concerns.

Do you provide after sales services as my project is not in China?

A:Of coure.Our sales and technician will reply to you on the day or next day (time gap) .We think highly of after sales service as a reputed DAF and Lamella clarifier brand manufacturer.