Case of High Efficient Sedimentation DAF System -Gelatin Wastewater Treatment Process

Case 2022年8月2日 2,432

Project:

Large-scale gelatin production enterprise Wastewater Treatment Process Pretreatment Facility Retrofit.

Industry:

Gelatin Manufacturer

Wastewater Description:

Gelatin is produced by processing animal skin, bone, sarcolemma and other tissues. The finished gelatin products usually go through more than a dozen processes such as classification, washing and dipping, degreasing, neutralization, hydrolysis, filtration, concentration, gelation, drying, and crushing. The production process will produce a large amount of waste water. The waste water contains a large amount of oil, suspended solids, high concentrations of COD and other pollution factors. The sewage must be treated to meet emission standards.

Customers meets problems:

1. There are wastewater facilities with a treatment capacity of about 8000m3/d. The process is: production drainage → mechanical grid → cavatationair flotation → adjustment tank → secondary air flotation → primary sedimentation tank → series of biochemical processes.In the incoming water ditch, there is only one 5mm mechanical grille to intercept, which has limited effect on the removal rate of grease from wastewater. Although the two-stage air flotation process equipment is turned on, but no micro-bubbles are generated, and the removal efficiency of oil and suspended solids is not obvious. At the same time, a lot of chemicals and energy consumption are wasted. The poor performance of the pretreatment facilities resulted in high load of the secondary biological treatment system, unstable operation, and large fluctuations in the effluent index.

2. In its washing and dipping production process, the acid washing and alkaline washing procedures are carried out in stages. The wastewater has strong acidity or alkalinity, and the incoming water has not been homogeneously adjusted, so the primary treatment equipment is seriously corroded; the wastewater contains high Concentrations of Cl- and SO42- will seriously corrode the steel structure equipment in the pretreatment section.

Solutions we offer:

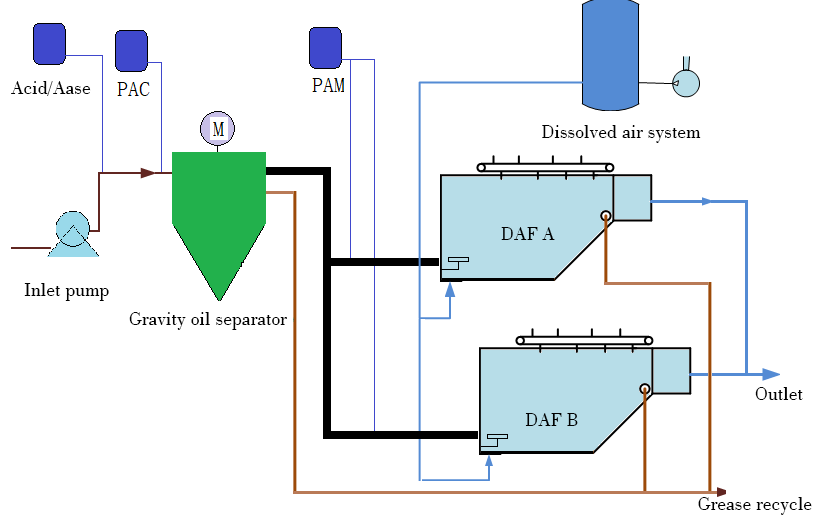

Based on the current situation, improving the oil removal efficiency of the pretreatment section is the focus of this project. Added dissolved air coagulation flotation, which is the core of the pretreatment section. Due to the high oil concentration in the incoming water, the air flotation and return ratio should not be less than 40%, and the site area is preferred. This time, high efficient sedimentation dissolved air flotation was selected, and the hydraulic load reached 9m3/m2*h. This air flotation optimizes the flow state of the separation zone. , increase the wetted area of the separation zone, greatly reduce the Reynolds number, effectively improve the conditions of the separation zone, and make the water flow in the separation zone in a laminar flow state.

This sewage facility is specially designed for the treatment of concentrated acid water and concentrated alkaline water. This type of wastewater has the characteristics of high concentration of grease and SS, strong corrosion, and large fluctuation of water volume. The design of the air flotation system has a maximum processing capacity of 200m3/h.

Optimal design of dissolved air system: Due to the high solid content of incoming water, the design of the dissolved air reflux ratio needs to be appropriately enlarged, and should not be lower than 45%; in order to reduce the frequency of blockage of the releaser, the releaser should be designed with anti-clogging and no disassembly and cleaning capabilities. At the same time, the influence of the waste water medium on the corrosion and failure of the instrument in the later stage are considered.

Air flotation machine selection: the hydraulic load is conservatively set at 5.5-7.0m3/m2*h; the air flotation area is equipped with a sludge hopper to facilitate sludge discharge; during the air flotation process, there is a large amount of floating grease and suspended matter, and the entire area of the sludge skimmer covering, no dead corner scraping, the more conferted scraper greatly reduces the interference of the scraper to the air flotation operation, and improves the scraping efficiency.

Result:

The pretreatment system operates stably, and the removal rate of animal oils and fats in wastewater is greater than 95%. The effluent of the system can be directly discharged into the wastewater station for biochemical treatment.

At the same time, the oil separated by this system can be recycled and refined into industrial oil, which has high economic value, and the annual income of millions of dollars depends on oil recovery.

Contact Us

- Room 501-5, Building 8, Longdong Avenue 3000, Pudong New District, Shanghai, China

- +86-18918301201

- Grace Xia

- jorsun01@jorsun.com.cn