Introduction to Waste Plastic Bottle Cleaning Sewage:

Waste plastic bottle recycling and cleaning sewage is generated during the recycling and cleaning process of waste plastic bottles, mainly from the pretreatment, cleaning, and sorting stages of waste plastic bottles. This type of sewage contains a variety of pollutants, including solvents, plasticizers, stabilizers, flame retardants, pigments, etc., added during the processing of plastic bottles, as well as oil stains, dust, and other attachments on the surface of plastic bottles.

Characteristics of Waste Plastic Bottle Cleaning Sewage Treatment:

Due to the complex sources of waste plastic bottles, the pollutants in the cleaning sewage are diverse, with large fluctuations in concentration, and often have poor degradability. The sewage has a high content of suspended solids (SS) and may contain heavy metals and toxic substances, posing a threat to the environment and human health. In addition, the pH value, temperature, and color of the sewage may also vary greatly due to different types of plastic bottles and cleaning processes.

Waste Plastic Bottle Cleaning Sewage Treatment Process:

The treatment of waste plastic bottle recycling and cleaning sewage usually requires a comprehensive treatment process that combines physical, chemical, and biological methods. First, physical methods such as screens, sedimentation, or flotation are used to remove suspended solids and some dissolved pollutants. Then, chemical methods such as coagulation sedimentation or adsorption are used to further remove organic matter and heavy metals. Finally, biological treatment methods are used to degrade biodegradable organic matter, in order to purify water quality and reduce environmental pollution.

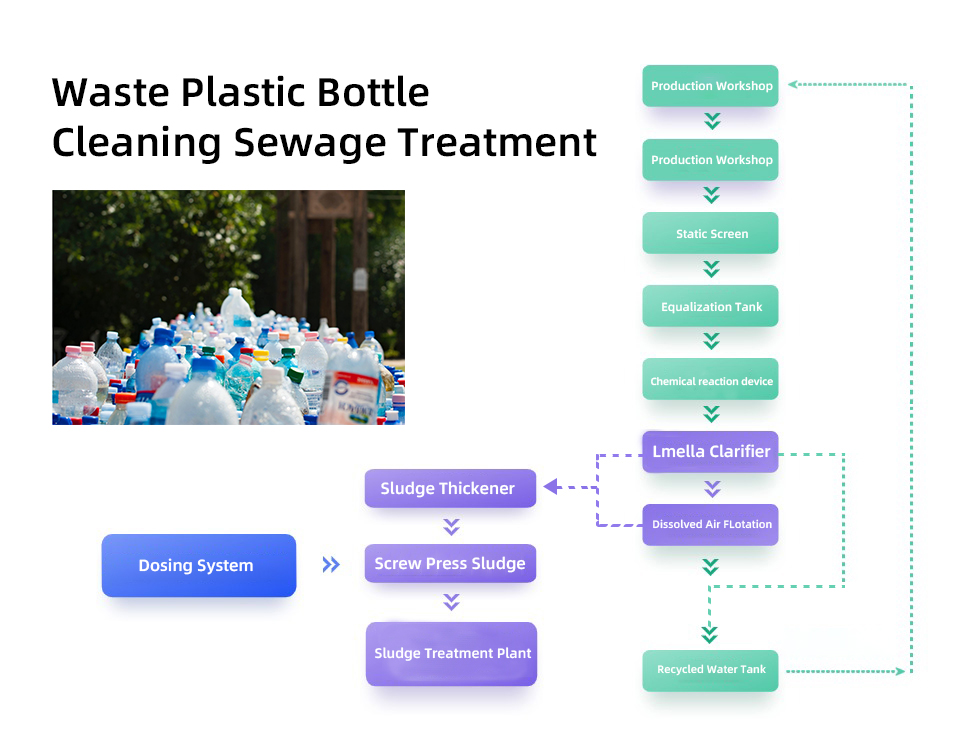

The following is the process flow of the waste plastic bottle cleaning sewage treatment system:

As shown in the figure, the waste plastic bottle cleaning sewage generated in the workshop first flows into the screen, and after preliminary filtration to remove large particles of impurities, it flows into the regulation pool. The sewage in the regulation pool is pumped into the coagulation reaction pool, where it is fully mixed and reacted with coagulants and flocculants, and then enters the lamella clarifier for sedimentation separation. If there are still some suspended solids in the effluent from the clarifier, its effluent can enter the dissolved air flotation device for further removal of suspended solids in the water, thereby reaching the reuse standard. The treated sewage flows into the intermediate pool for production use.

The sludge generated from the lamella clarifier and dissolved air flotation machine is sent to the sludge thickening pool, and then pumped into the sludge dewatering machine, mixed with the reagent added by the dosing device, and treated. The treated sludge is transported outside for centralized treatment at a dedicated sludge treatment factory. The advantages of this integrated sewage treatment system are: small footprint, simple and practical. Automated control, easy operation and management. Strong resistance to impact load. Simple construction of sewage treatment facilities, low investment. Low power consumption, small dosage of medicine, small amount of residual sludge, low operating costs. Low noise, no adverse effects on the surrounding environment.

The functions of the related treatment processes are as follows:

Screens: Remove solid and large solid impurities from sewage.

Regulation pool: Regulate the water quality and quantity of sewage, and quantitatively lift to the lamella clarifier.

Lamella clarifier: Used to utilize the gravity settling action of particles or flocs to remove suspended solids from the water and purify the water quality.

Dissolved air flotation: Used to remove suspended solids (SS) from the water, with an SS removal rate that can reach 75% to 95%, and a function to reduce COD, with a COD removal rate that can reach 50% to 65%, and also has decolorization and oil removal functions.

Intermediate pool: The intermediate pool mainly serves as a transition, collecting sewage after flotation treatment.

Sludge treatment system: The residual sludge from the sewage treatment system is discharged into the sludge thickening pool, and after thickening, it is lifted by the pump to the spiral sludge dewatering machine for sludge dewatering, and the dry mud is transported outside for disposal or landfill disposal by a dedicated sludge disposal factory.

High-efficiency Lamella Clarifier Accelerates Sedimentation Speed:

The high-efficiency lamella clarifier uses the principle of shallow sedimentation to shorten the sedimentation time by shortening the settling distance of particles. By adding plates in the sedimentation tank, it not only increases the sedimentation area but also shortens the sedimentation time. Lamella plate or tube sedimentation tanks use the principle of laminar flow, allowing water to flow between the plates or tubes, with a small hydraulic radius and a low Reynolds number, making the water flow in a laminar state, which is conducive to sedimentation.

Dissolved Air Flotation Rapidly Removes Suspended Solids:

In the sewage treatment process of waste plastic bottles, dissolved air flotation can effectively separate and remove suspended solids and grease from the sewage. This technology uses the buoyancy of microbubbles to lift insoluble solid particles and grease to the surface of the water, thus achieving solid-liquid separation. The water quality is improved after treatment by the dissolved air flotation machine, with a significant reduction in suspended solids and grease content.

The purified sewage can reach the reuse standard and can be used in the factory’s recycling water system, effectively reducing the factory’s dependence on and consumption of water resources, achieving sustainable use of water resources. Through this closed-loop water treatment and reuse system, the factory not only reduces its impact on the environment but also reduces operating costs and improves economic benefits